Uwukhetha njani uMphezulu wokuGqibela kuYilo lwePCB yakho

Ⅲ Isikhokelo sokhetho kunye neendlela zokuphuhlisa

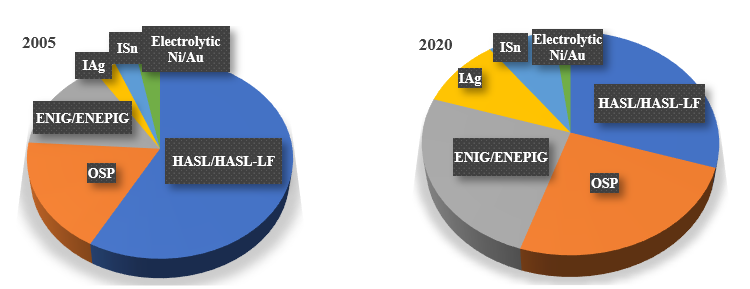

Njengoko le tshati ingentla ibonisa, iPCB yokugqiba umphezulu usetyenziso iye yahluka ngokumangalisayo kule minyaka ingama-20 idlulileyo njengoko iteknoloji iphuhla kunye nobukho bezalathiso ezihambelana nokusingqongileyo.

1) I-HASL iKhokela mahala.I-Electronics yehle kakhulu kubunzima kunye nobukhulu ngaphandle kokuncama ukusebenza okanye ukuthembeka kwiminyaka yakutshanje, oko kuthintele ukusetyenziswa kwe-HASL ukuya kumlinganiselo omkhulu onomphezulu ongalinganiyo kwaye awufanelekanga kwi-pitch entle, i-BGA, ukubekwa kwamacandelo amancinci kwaye ifakwe kwimingxuma.Ukugqitywa komgangatho womoya oshushu kunomsebenzi omkhulu (ukuthembeka, ukuthengiswa, indawo yokuhlala yomjikelo we-thermal kunye nobomi obude beshelufu) kwindibano yePCB eneepads ezinkulu kunye nesithuba.Yenye yezona zinto zifikelelekayo kwaye zikhoyo.Nangona itekhnoloji ye-HASL iye yaguqulelwa kwisizukulwana esitsha se-HASL ekhokelela kwimiqathango ye-RoHS ethobelayo kunye nemiyalelo ye-WEEE, ukugqiba komgangatho womoya oshushu wehla ukuya kwi-20-40% kwishishini lokwenziwa kwe-PCB ekubeni lilawule (3/4) kule ndawo ngo-1980s.

2) OSP.I-OSP yayidumile ngenxa yeendleko eziphantsi kunye nenkqubo elula kunye neepads ezidibeneyo.Isamkelwa ngenxa yoku.Inkqubo yokugquma i-organic ingasetyenziswa ngokubanzi zombini kwii-PCB eziqhelekileyo okanye ii-PCB eziphambili ezifana ne-pitch entle, i-SMT, iibhodi zokukhonza.Uphuculo lwakutsha nje kwipleyiti ye-multilayer ye-organic coating iqinisekisa ukuba i-OSP ime imijikelo emininzi yokuthengisa.Ukuba i-PCB ayinazo iimfuno zokusebenza koqhagamshelwano lomphezulu okanye imida yobomi beshelufu, i-OSP iya kuba yeyona nkqubo ifanelekileyo yokugqiba umphezulu.Nangona kunjalo iziphene zayo, ubuntununtunu bokuphatha umonakalo, ubomi obufutshane beshelufu, ukungaziphathi kakuhle kunye nobunzima bokuhlola ukucotha inyathelo layo ukuze libe namandla ngakumbi.Kuqikelelwa ukuba malunga ne-25% -30% ye-PCBs okwangoku zisebenzisa inkqubo yokwaleka kwezinto eziphilayo.

3) ENIG.I-ENIG sesona siphelo sidumileyo phakathi kwee-PCB eziphambili kunye nee-PCB ezisetyenziswa kwindawo erhabaxa, ngokusebenza kwayo okugqwesileyo kumphezulu weplani, ukuqina kunye nokuqina, ukuxhathisa ukonakala.Uninzi lwabavelisi be-PCB bane-nickel engena-electroless / imigca yegolide yokuntywiliselwa kwiifektri zabo zeebhodi zeesekethe okanye iindibano zocweyo.Ngaphandle kokuqwalasela iindleko kunye nolawulo lwenkqubo, i-ENIG iya kuba yeyona ndlela ifanelekileyo ye-HASL kwaye iyakwazi ukusetyenziswa ngokubanzi.I-nickel engenambane/igolide yokuntywiliselwa yayikhula ngokukhawuleza ngeminyaka yoo-1990s ngenxa yokusombulula ingxaki yokuba caba yomgangatho womoya oshushu kunye nokususwa kokuguquguquka okugqunywe ngokwasemzimbeni.I-ENEPIG njengoguqulelo oluhlaziyiweyo lwe-ENIG, yayisombulula ingxaki yepedi emnyama ye-electroless nickel / igolide yokuntywiliselwa kodwa ngelixa isabiza.Usetyenziso lwe-ENIG lunokucotha kancinci ukusukela ekunyukeni kwexabiso eliphantsi lokutshintshwa okufana ne-Immersion Ag, iTin yokuntywila kunye ne-OSP.Kuqikelelwa malunga ne-15-25% yee-PCBs ngoku ezisamkelayo esi sigqibo.Ukuba akukho bhondiso lohlahlo lwabiwo-mali, i-ENIG okanye i-ENEPIG lukhetho olufanelekileyo kwiimeko ezininzi ngakumbi kwii-PCBs ezineemfuno ezifunwa kakhulu ze-inshurensi ekumgangatho ophezulu, itekhnoloji yepakethe entsonkothileyo, iintlobo ezininzi ze-soldering, imingxunya, intambo yocingo, kunye netekhnoloji yokucofa. njl..

4) Ukuntywiliselwa kwesilivere.Njengokutshintsha ngexabiso eliphantsi kwe-ENIG, isilivere yokuntywiliselwa ineepropathi ezinomphezulu othe tyaba, ukuqhuba okuhle, ubomi beshelufu obuphakathi.Ukuba iPCB yakho ifuna i-pitch entle / i-BGA SMT, ukubekwa kwezixhobo ezincinci, kwaye ifuna ukugcina umsebenzi woqhagamshelo kakuhle ngelixa unohlahlo lwabiwo-mali olusezantsi, isilivere yokuntywiliselwa lolona khetho lukhethekileyo kuwe.I-IAg isetyenziswa kakhulu kwiimveliso zonxibelelwano, iimoto, kunye neeperipherals zekhompyutha, njl.Ukukhula kwesilivere yokuntywiliselwa kuyacotha (kodwa sisanyuka) ngenxa yokwehla nokuba nengqiqo ukungcolisa kunye nokuba ne-solder joint voids.Kukho malunga ne-10% -15% yee-PCBs ezisebenzisayo ngoku oku kugqitywa.

5) Ukuntywiliselwa kwiTin.I-Tin yokuntywiliselwa iye yaziswa kwinkqubo yokugqiba umphezulu ngaphezu kweminyaka engama-20.I-automation yemveliso ngoyena mqhubi we-ISn umphezulu wokugqiba.Lolunye ukhetho olungabizi kakhulu kwiimfuno zomphezulu osicaba, ukubekwa kwezixhobo zepitch entle kunye nokulingana kocinezelo.I-ISn ifanelekile ngakumbi kwiinqwelomoya zonxibelelwano akukho naziphi na izinto ezintsha ezongeziweyo ngexesha lenkqubo.I-Tin Whisker kunye nefestile yokusebenza emfutshane ngumlinganiselo omkhulu wesicelo sayo.Iintlobo ezininzi zokudibanisa azikhuthazwa ukuba zinikwe ukunyuka kwe-intermetallic layer ngexesha le-soldering.Ukongezelela, ukusetyenziswa kwenkqubo yokuntywiliselwa kwe-tin kuthintelwe ngenxa yobukho be-carcinogens.Kuqikelelwa ukuba malunga ne-5% -10% yee-PCBs ngoku zisebenzisa inkqubo yokuntywiliselwa kwetoti.

6) Electrolytic Ni/Au.I-Electrolytic Ni/Au ngumsunguli weteknoloji yonyango lomphezulu we-PCB.Ivele ngengxakeko yeebhodi zeesekethe eziprintiweyo.Nangona kunjalo, ixabiso eliphezulu kakhulu linciphisa ngokumangalisayo ukusetyenziswa kwayo.Kule mihla, igolide eSoft isetyenziswa ikakhulu kwiingcingo zegolide kwi-chip package;Igolide elukhuni isetyenziswa ikakhulu kuqhagamshelo lombane kwiindawo ezingathengiswanga njengeminwe yegolide kunye nabathwali be-IC.Umyinge we-Electroplating Nickel-gold umalunga ne-2-5%.

EmvakwiiBlogs

Ixesha lokuposa: Nov-15-2022