ithunyelwe: NgoFebruwari 15, 2022

Iindidi:Iiblogi

Iithegi:pcb, pcbs, pcba, pcb assembly, smt, stencil

Yintoni i-PCB Stencil?

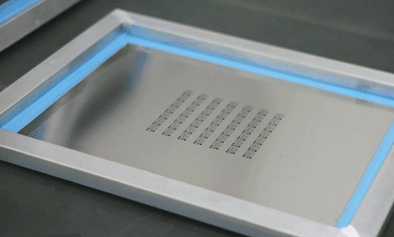

I-PCB Stencil, ekwabizwa ngokuba yi-Steel mesh, liphepha le-stai

intsimbi engenanto enezivulo zokusikwa kwelaser ezisetyenziselwa ukuhambisa isixa esichanekileyo sokuncamathelisa i-solder kwindawo echanekileyo echongiweyo kwi-PCB engenanto yokubekwa kwamacandelo.I-stencil yenziwe ngesakhelo se-stencil, i-wire mesh kunye neshidi lensimbi.Kukho imingxunya emininzi kwi-stencil, kwaye izithuba zale mingxuma zihambelana nezikhundla ezifuna ukushicilelwa kwi-PCB.Umsebenzi oyintloko we-stencil ukubeka ngokuchanekileyo umlinganiselo ochanekileyo wokunamathisela i-solder kwi-pads ukwenzela ukuba i-solder joint phakathi kwe-pad kunye necandelo ligqibelele ngokuhambelana nombane kunye namandla omatshini.

Xa isetyenziswa, beka iPCB phantsi kwestencil, Kanye xa i

i-stencil ihambelana ngokufanelekileyo phezu kwebhodi, i-solder paste isetyenziswe phezu kokuvuleka.

Emva koko intlama ye-solder ivuza kumphezulu we-PCB ngemingxunya emincinci kwindawo emiselweyo kwistencil.Xa i-foil yensimbi ihlukaniswe kwibhodi, i-solder paste iya kuhlala phezu kwebhodi yesiphaluka, ilungele ukubekwa kwezixhobo zokunyuka kwendawo (SMDs).Ukuncamathisela kwe-solder encinci kuvaliwe kwi-stencil, ngakumbi ifakwe kwi-PCB.Le nkqubo inokuphinda iphindwe ngokuchanekileyo, ngoko ke yenza inkqubo ye-SMT ikhawuleze kwaye ihambelane ngakumbi kwaye iqinisekise ukuba iindleko ze-PCB Assembly.

Yenziwe ngantoni i-PCB Stencil?

I-stencil ye-SMT yenziwe ngokukodwa ngefreyimu ye-stencil, i-mesh kunye

ishidi lensimbi engenasici, kunye neglu.Isakhelo se-stencil esisetyenziswa ngokuqhelekileyo yisakhelo esincanyathiselwe kumnatha wocingo ngeglu, ekulula ukufumana iyunifomu yoxinzelelo lwamaphepha entsimbi, oluyi-35 ~ 48N / cm2.I-Mesh yeyokulungisa iphepha lentsimbi kunye nesakhelo.Kukho iindidi ezimbini zemeshes, intsimbi engenastainless wire mesh kunye ne polymer polyester mesh.Eyangaphambili inokubonelela ngoxinzelelo oluzinzileyo kunye olwaneleyo kodwa kulula ukuyikhubaza kwaye iguge.Okuya mva kodwa kunokuhlala ixesha elide xa kuthelekiswa nomnatha wocingo lwentsimbi.Ngokuqhelekileyo iphepha le-stencil elamkelekileyo liyi-301 okanye i-304 ye-stainless steel sheet ephucula ngokucacileyo ukusebenza kwe-stencil ngokusebenzisa iimpawu zayo ezibalaseleyo.

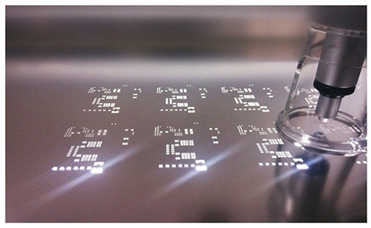

Indlela yokuvelisa yeStencil

Kukho iintlobo ezisixhenxe zeestencils kunye neendlela ezintathu zokwenza i-stencils: i-chemical etching, i-laser cutting kunye ne-electroforming.Ngokuqhelekileyo isetyenziswa yi-laser steel stencil.Las

I-er stencil yeyona isetyenziswa kakhulu kwishishini le-SMT, ephawulwe ngolu hlobo:

Ifayile yedatha isetyenziselwa ngokuthe ngqo ukunciphisa impazamo yokuvelisa;

Indawo yokuvula ichanekile yestencil ye-SMT iphezulu kakhulu: yonke impazamo yenkqubo ≤± 4 μ m;

Ukuvulwa kwe-stencil ye-SMT kune-geometry, eyi-conduci

kushicilelo kunye nokubumba i-solder paste.

Ukuhamba kwenkqubo yokusika iLaser: ukwenza ifilimu iPCB, ukuthatha ulungelelwaniso, ifayile yedatha, ukusetyenzwa kwedatha, ukusika i-laser, ukugaya.Inkqubo inokuchaneka kwemveliso yedatha ephezulu kunye nefuthe elincinci leenjongo;Ukuvulwa kweTrapezoidal kukulungele ukudiliza, kungasetyenziselwa ukusika ngokuchanekileyo, ixabiso elincinci.

Iimfuno jikelele kunye nemigaqo PCB Stencil

1. Ukufumana ushicilelo olugqibeleleyo lwe-solder pads kwi-PCB pads, indawo ethile kunye neenkcukacha ziya kuqinisekisa ukuchaneka kokuvula okuphezulu, kwaye ukuvulwa kuya kuba ngokuhambelana ngokungqongqo kunye nendlela yokuvula ekhankanyiweyo ekubhekiselwe kumanqaku e-fiducial.

2. Ukunqanda iziphene ze-solder ezifana ne-bridging kunye namaso e-solder, ukuvula okuzimeleyo kuya kuyilwa kancinci kunobungakanani bephedi ye-PCB.ububanzi bubonke abuyi kuba ngaphezu kwe-2mm.Ummandla we-PCB pad kufuneka uhlale ungaphezulu kwesibini kwisithathu sommandla wangaphakathi wodonga lokuvula lwe-stencil.

3. Xa wolula i-mesh, yilawule ngokungqongqo, kunye ne-pa

y ingqalelo ekhethekileyo kuluhlu lokuvula, okufuneka lube tye kwaye lugxile.

4. Ngomphezulu wokushicilela njengomphezulu, ukuvuleka okuphantsi komnatha kuya kuba yi-0.01mm okanye i-0.02mm ububanzi kunokuvulwa okuphezulu, oko kukuthi, ukuvuleka kuya kuguqulelwa i-conical ukuze kube lula ukukhululwa okusebenzayo kwe-solder paste kunye nokunciphisa ukucoca. amaxesha estencil.

5. Umnatha wodonga kufuneka ube mpuluswa.Ngokukodwa kwi-QFP kunye ne-CSP enesithuba esingaphantsi kwe-0.5mm, umthengisi kufuneka aqhube i-electropolishing ngexesha lenkqubo yokuvelisa.

6. Ngokuqhelekileyo, inkcazo yokuvula i-stencil kunye nokuma kwamacandelo e-SMT ahambelana ne-pad, kwaye umlinganiselo wokuvula ngu-1: 1.

7. Ubukhulu obuchanekileyo bephepha le-stencil buqinisekisa ukukhululwa

yesixa esifunwayo sokuncamathelisa i-solder ngokuvula.Ukubekwa kwe-solder eyongezelelekileyo kunokubangela ibhulorho ye-solder ngelixa ukubekwa kwe-solder encinci kuya kubangela ukuba amalungu abuthathaka.

Uyila njani i-PCB Stencil?

1. Iphakheji ye-0805 inconywa ukuba inqumle iipads ezimbini zokuvula nge-1.0mm, uze wenze isangqa se-concave B = 2 / 5Y;A = 0.25mm okanye a = 2 / 5 * l anti tin bead.

2. I-Chip 1206 nangaphezulu: emva kokuba iipads ezimbini zihanjiswe ngaphandle nge-0.1mm ngokulandelanayo, yenza isangqa sangaphakathi se-concave B = 2 / 5Y;A = 2 / 5 * l unyango anti tin bead.

3. Kwi-PCB ene-BGA, umlinganiselo wokuvula we-stencil kunye nesithuba sebhola esingaphezu kwe-1.0mm ngu-1: 1, kunye nomlinganiselo wokuvula we-stencil kunye nesithuba sebhola esingaphantsi kwe-0.5mm yi-1: 0.95.

4. Kuzo zonke i-QFP kunye ne-SOP ene-0.5mm pitch, i-rati yokuvula

o kububanzi bubonke icala yi-1:0.8.

5. Umlinganiselo wokuvula kwindlela yobude ngu-1: 1.1, kunye ne-0.4mm pitch QFP, ukuvulwa kwinqanaba lobubanzi bubonke ngu-1: 0.8, ukuvulwa kubude obuyi-1: 1.1, kunye nonyawo olujikelezayo lwangaphandle.Chamfer radius r = 0.12mm.Ububanzi obupheleleyo bokuvula bento ye-SOP ene-0.65mm pitch iyancipha nge-10%.

6. Xa i-PLCC32 kunye ne-PLCC44 yeemveliso eziqhelekileyo zifakwe i-perforated, ulwalathiso lobubanzi bubonke ngu-1: 1 kunye nobude be-1: 1.1.

7. Kwizixhobo ezipakishwe ngokubanzi zeSOT, umlinganiselo wokuvula

Isiphelo sephedi enkulu yi-1:1.1, ububanzi bubonke becala lesiphelo sephedi yi-1:1, kwaye ubude becala yi-1:1.

NjaniUkusebenzisa i-PCB Stencil?

1. Phatha ngenyameko.

2. I-stencil iya kucocwa ngaphambi kokusetyenziswa.

3. I-solder paste okanye iglue ebomvu iya kusetyenziswa ngokulinganayo.

4. Lungisa uxinzelelo loshicilelo kokona kulungileyo.

5. Ukusebenzisa ushicilelo lwepastebhodi.

6. Emva kwe-scraper stroke, kungcono ukuyeka i-2 ~ 3 imizuzwana ngaphambi kokudiliza, kwaye usete isantya sokudiliza singakhawulezi kakhulu.

7. Istencil iya kucocwa ngexesha, igcinwe kakuhle emva kokusetyenziswa.

Inkonzo yokwenziwa kweStencil yePCB ShinTech

I-PCB ShinTech ibonelela ngeenkonzo zokwenza iistencil zentsimbi yelaser.Senza iistencils ezinobunzima be-100 μm, 120 μm, 130µm, 150 μm, 180 μm, 200 μm, 250 μm kunye ne-300 μm.Ifayile yedatha efunekayo ukwenza i-laser stencil kufuneka iqulathe i-SMT solder paste layer, idatha ye-fiducial mark, i-PCB ye-outline layer kunye ne-character layer, ngoko sinokujonga amacala angaphambili nangasemva kwedatha, icandelo lecandelo, njl.

Ukuba ufuna ikhowuti nceda uthumele iifayile zakho kunye nombuzo kusales@pcbshintech.com.

Ixesha lokuposa: Jun-10-2022